-

+86-577-57156888

-

-

+86-577-57155869

-

11th Floor, Building 6, Headquarters Economic Park, Yueqing, Zhejiang, China

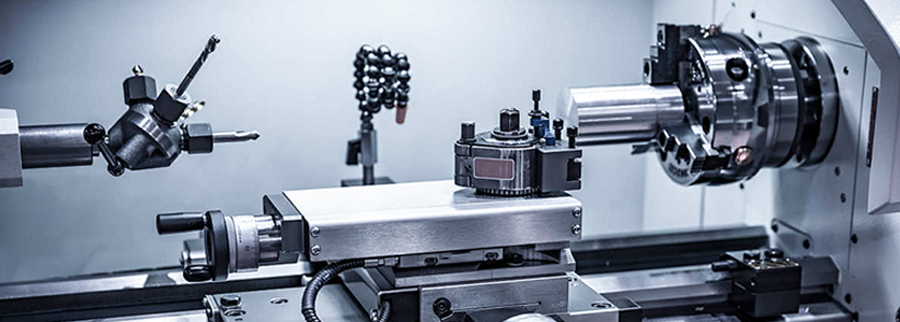

CNC Machine Tools

In the CNC machine tool industry, soft starters and frequency converters each have their unique applications.

- Application of soft starters in the CNC machine tool industry:

1. Smooth start and reduced impact:

The motors in CNC machine tools often generate large starting currents when starting, which may cause impacts on the power grid and equipment. The soft starter controls the input voltage to gradually increase the starting current of the motor, thereby achieving a smooth start. This helps to reduce the current impact and mechanical impact at startup and protect the motor and machine tool equipment

2. Protect the motor and extend the service life:

The soft starter not only has the starting function but also provides a variety of protection functions such as overload protection. In CNC machine tools, this helps to extend the service life of the motor and reduce motor damage caused by starting impact or overload

3. Suitable for occasions with frequent starting:

CNC machine tools may need to start and stop the motor frequently during processing. Soft starters are economical and easy to use, making them particularly suitable for such occasions where frequent starting is required. They can effectively reduce the impact of starting current on the power grid and equipment.

- Application of frequency converters in the NC machine tool industry:

1. Speed regulation and improved processing accuracy:

The frequency converter can change the running speed of the AC motor and achieve precise speed regulation of the motor by adjusting the frequency of the power supply. In CNC machine tools, this helps to adjust the motor speed according to processing requirements, thereby improving processing accuracy and efficiency.

2. Energy saving and energy reduction:

The frequency converter adjusts the motor speed to reduce energy consumption when the motor is running at non-essential high speed. In CNC machine tools, this helps to save electricity costs and improve the energy efficiency of equipment.

3. Realization of complex control functions:

The frequency converter not only has the speed regulation function but also can realize a variety of complex control functions such as forward and reverse control and braking of the motor. In CNC machine tools, this helps meet complex processing requirements and improve the flexibility and automation of equipment.

4. Improve machine tool performance and reliability:

After adopting variable frequency speed regulation, the original complex mechanical transmission mechanism, such as the gearbox, can be simplified, thereby improving the reliability and stability of the machine tool. At the same time, the frequency converter can also provide functions such as overload protection to further ensure the safe operation of the machine tool.

In summary, soft starters and frequency converters each have their unique application value in the CNC machine tool industry. Soft starters are favored for their smooth starting, motor protection, and suitability for frequent starting occasions; while frequency converters are widely used for their advantages of precise speed regulation, energy saving and consumption reduction, and realization of complex control functions.

English

English 中文简体

中文简体 عربى

عربى

浙公网安备33038202003754号

浙公网安备33038202003754号