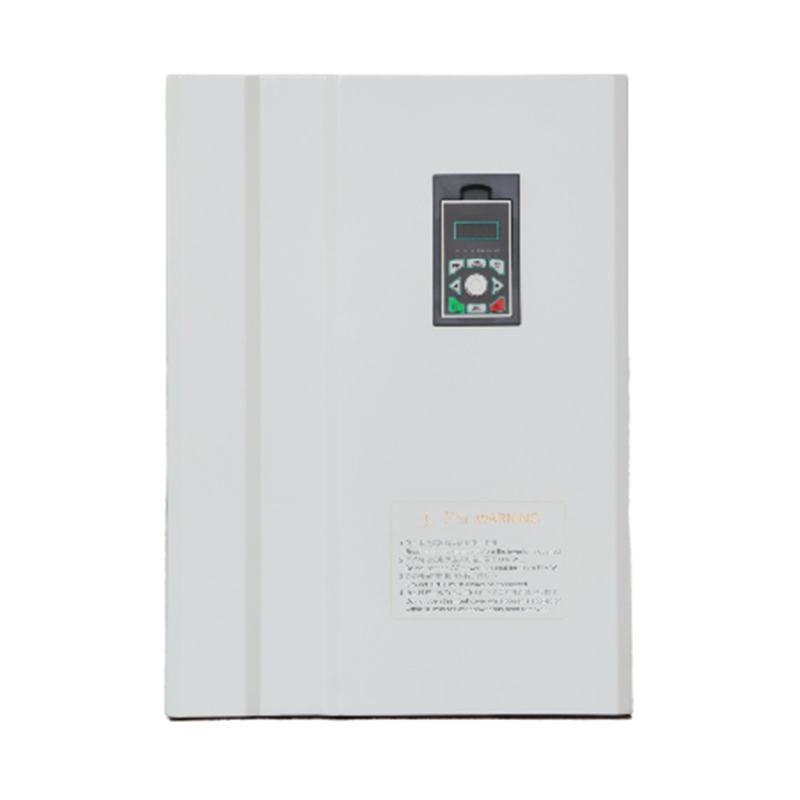

Product Advantages

1. Wide Frequency Output Range

- The 820 General-purpose Inverter can output frequencies ranging from 0 to 500Hz, providing precise speed control for a variety of applications.

- For specialized industries, the inverter can be configured to operate at frequencies up to 3000Hz, offering even more flexibility for high-demand use cases.

2. Multiple Speed Control Modes

- Sensorless Vector Control (SVC): This mode provides excellent motor starting torque as low as 0.5Hz, with a torque boost of up to 150%, making it suitable for applications that require high starting power.

- V/F Control: This mode is effective for general motor control, providing smooth operation and efficient speed regulation.

- Closed-loop Vector Control: For applications requiring precise speed and torque control, the closed-loop vector control mode ensures excellent performance under varying load conditions.

3. Robust Overload Capability

- The 820 General-purpose Inverter offers impressive overload handling capability, supporting up to 150% overload for one minute. This ensures reliability and prevents failure during high-torque situations or rapid load changes.

4. Flexible Frequency Settings

- Users can configure multiple frequency setting methods such as digital, analog, PID, multi-speed, simple PLC, PULSE, and RS485 communication settings.

- This flexibility allows for easy integration into different types of automation systems and adapts to specific application requirements.

5. Advanced PID Control and Programmability

- Built-in PID control allows for precise regulation of process variables such as speed, temperature, or pressure.

- The PIDDISABLE function provides additional flexibility by allowing users to deactivate PID control when not needed.

- The inverter also supports multiple operating modes via fully programmable I/O terminals, enabling customized control schemes for various industrial processes.

Product Applications

1. Textile Industry

- The 820 General-purpose Inverter is widely used in textile manufacturing, including machines for spinning, weaving, and dyeing.

- Its ability to provide stable motor control at varying speeds ensures consistent fabric production, improving operational efficiency and reducing energy consumption.

- The advanced PID control helps maintain precise conditions during critical processes like dyeing or finishing, ensuring high-quality output.

2. Paper Manufacturing

- In the paper industry, the inverter is ideal for controlling motors in paper mills, pulp processing, and paper-making machines.

- The flexibility in frequency control allows for smooth and efficient operation across different stages of paper production, enhancing throughput and product quality.

- The inverter’s overload protection ensures safe operation in high-load applications, such as during the pulping and drying processes.

3. Water Pumps and Fans

- The 820 General-purpose Inverter is frequently used in water pumps and ventilation fans, where maintaining consistent motor performance across varying load conditions is essential.

- Its ability to adjust speed and reduce energy consumption makes it ideal for applications in water treatment facilities, HVAC systems, and industrial fans.

- The fault protection features help prevent damage during power surges, ensuring the longevity of both the inverter and the connected motors.

English

English 中文简体

中文简体 عربى

عربى

浙公网安备33038202003754号

浙公网安备33038202003754号